close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-10-14 Origin: Site

When it comes to tubing materials, PTFE and FEP stand out for their unique properties. Understanding their differences is crucial for selecting the right material for specific applications. In this post, you'll learn about their chemical structures, thermal properties, mechanical strength, and more, helping you make informed choices for various industries.

Understanding the chemical structure of PTFE and FEP tubing is key to grasping their different properties and applications.

PTFE, or polytetrafluoroethylene, is made from a single type of monomer called tetrafluoroethylene (TFE). This means its polymer chains consist entirely of repeating TFE units. Each carbon atom in the chain is bonded to two fluorine atoms, creating a strong, stable structure. This homopolymer setup gives PTFE its famous qualities: high melting point, excellent chemical resistance, and very low friction. The lack of branching or cross-linking in the polymer chains means PTFE is highly crystalline and thermally stable.

FEP, or fluorinated ethylene propylene, differs because it’s a copolymer. It combines tetrafluoroethylene (TFE) with another monomer called hexafluoropropylene (HFP). The presence of HFP units disrupts the regularity of the polymer chain, reducing crystallinity. This structural difference lowers FEP’s melting point compared to PTFE and allows it to be melt-processed. The copolymer structure also grants FEP superior flexibility and easier fabrication options, such as welding and molding.

The chemical makeup directly influences how these materials behave:

● Melting and Processing: PTFE’s homopolymer chains result in a very high melting point and no true melting phase, making it difficult to process by melting. FEP’s copolymer chains lower its melting point, enabling melt processing techniques.

● Mechanical Properties: PTFE is stiffer and more resistant to creep because of its crystalline, uniform structure. FEP’s disrupted chain structure makes it softer and more flexible.

● Chemical Resistance: Both are highly inert, but PTFE’s tighter polymer chains provide slightly better resistance to aggressive chemicals, especially at high temperatures.

● Transparency: FEP’s copolymer nature allows it to be transparent, useful for applications requiring visual inspection, whereas PTFE is translucent to opaque.

This chemical structure difference explains why PTFE suits high-temperature, high-wear uses, while FEP fits applications needing flexibility and ease of manufacturing.

PTFE tubing can handle extreme temperatures, operating continuously from about -260°C (-450°F) up to +260°C (+500°F). This wide range makes PTFE one of the most heat-resistant fluoropolymers available. It maintains its structural integrity and performance even at these high temperatures. PTFE’s ability to withstand such heat is due to its highly crystalline homopolymer structure, which provides excellent thermal stability.

FEP tubing has a slightly narrower temperature range, typically from -268°C (-450°F) to +205°C (+400°F). While it remains flexible even at cryogenic temperatures, FEP cannot sustain the same high temperatures as PTFE. Its copolymer structure lowers the melting point, which limits its upper temperature threshold. However, FEP’s performance at low temperatures is exceptional, making it ideal for applications requiring flexibility in very cold environments.

Because of its superior heat tolerance, PTFE tubing suits applications involving prolonged exposure to high temperatures. These include chemical processing, aerospace components, and electrical insulation where heat resistance is critical. FEP tubing, with its easier processing and flexibility, is often chosen for applications needing moderate heat resistance combined with transparency or weldability, such as in instrumentation, cable coatings, and fluid handling systems.

PTFE tubing stands out for its excellent mechanical strength, especially under long-term stress. It resists creep — the slow deformation under constant load — much better than many other plastics. This resistance comes from its highly crystalline, uniform polymer chains. PTFE maintains its shape and structural integrity even when subjected to continuous or cyclic mechanical stress. It also offers outstanding wear resistance, making it ideal for parts exposed to friction and abrasion. This durability means PTFE tubing can last longer in applications like seals, gaskets, and bearing liners where mechanical reliability is critical.

FEP tubing, on the other hand, is more flexible and easier to shape. Its copolymer structure allows it to be melt-processed, which means manufacturers can mold, weld, and extrude it into complex shapes more efficiently. This flexibility translates to better impact resistance and the ability to bend without cracking, which is useful in applications requiring tubing that can navigate tight spaces or move without damage. However, FEP is less resistant to creep and wear compared to PTFE, so it may deform more under sustained mechanical loads. Despite this, its ease of processing and flexibility make it a preferred choice where tubing needs to be formed into intricate profiles or where flexibility is essential.

Because of these mechanical differences, PTFE tubing is best suited for demanding mechanical environments. It excels in high-wear, high-stress applications such as chemical processing seals, high-pressure fluid transfer, and mechanical components requiring long-term dimensional stability.

FEP tubing fits applications where flexibility and ease of fabrication outweigh extreme mechanical strength. It is commonly used in electrical insulation, fluid handling systems requiring transparency and flexibility, and in medical devices where tubing must conform to complex shapes without compromising chemical resistance.

In summary, PTFE offers superior mechanical strength and durability, ideal for harsh, high-stress environments. FEP provides flexibility and ease of processing, suited for applications needing complex shapes or bending without failure.

Both PTFE and FEP tubing offer exceptional chemical resistance, making them top choices for harsh and corrosive environments. PTFE stands out as the most chemically inert polymer available. Its tightly packed homopolymer chains create a nearly impenetrable barrier against a wide range of aggressive chemicals, including strong acids, alkalis, and solvents. This resistance remains stable even at elevated temperatures, which makes PTFE ideal for highly corrosive conditions.

FEP also exhibits excellent chemical resistance, though it is slightly less inert than PTFE. The copolymer structure introduces minor vulnerabilities under extreme chemical exposure or high temperatures, but for most industrial chemicals, FEP remains highly stable. Its chemical resistance covers acids, bases, and organic solvents, making it suitable for many applications where chemical exposure is a concern.

PTFE’s superior chemical inertness makes it the preferred material for environments involving highly reactive or concentrated chemicals. It withstands prolonged exposure without degradation, which is critical in chemical processing plants, pharmaceutical manufacturing, and aggressive cleaning systems.

FEP tubing, while not as chemically impervious as PTFE, offers a valuable balance of chemical resistance and flexibility. It suits environments where moderate chemical exposure occurs, especially when combined with the need for tubing transparency or easier fabrication. FEP’s resistance to UV radiation and weathering also makes it suitable for outdoor chemical applications.

● Chemical processing: PTFE tubing is widely used for lining pipes, valves, and reactors due to its unmatched chemical durability. FEP tubing also finds use in fluid transfer systems where flexibility and visual inspection are necessary.

● Pharmaceuticals: PTFE’s inertness ensures no contamination or reaction with sensitive compounds. FEP is employed in tubing for drug delivery systems requiring sterilization and flexibility.

● Food and beverage: Both materials resist cleaning agents and food acids, but PTFE’s higher temperature tolerance suits sterilization processes better.

● Semiconductor manufacturing: PTFE and FEP tubing handle aggressive chemicals and ultra-pure fluids, with PTFE preferred for extreme purity and chemical resistance.

● Aerospace and automotive: PTFE tubing resists fuel, oils, and hydraulic fluids, while FEP is used where chemical resistance combines with lightweight and flexible tubing needs.

PTFE is renowned for its excellent electrical insulation properties. It has a very high electrical resistivity, which means it effectively prevents the flow of electrical current. This makes PTFE tubing ideal for insulating wires and components in high-frequency and high-voltage applications. Its stable dielectric properties remain consistent over a wide temperature range, from cryogenic levels up to about 260°C (500°F). PTFE also exhibits a low dielectric constant and dissipation factor, minimizing signal loss in electronic circuits. These qualities make PTFE the preferred choice for demanding electrical insulation tasks where reliability and safety are critical.

FEP also offers impressive electrical insulation, but with some differences compared to PTFE. It has a high dielectric strength, which refers to the maximum electric field the material can withstand without breaking down. FEP's dielectric constant is slightly higher than PTFE's, but it still performs well in most electrical applications. One key advantage of FEP is its lower moisture absorption compared to many other polymers, helping maintain stable insulation even in humid environments. However, FEP’s maximum continuous operating temperature for electrical insulation is lower, typically around 200°C (392°F), which limits its use in extreme heat conditions. Its melt-processability allows manufacturers to produce thin, uniform coatings and tubing, making FEP popular for wire and cable insulation where flexibility and precision are needed.

Both PTFE and FEP tubing find extensive use in electronics and wiring. PTFE tubing is often used in aerospace, military, and high-end industrial electronics where superior temperature resistance and electrical insulation are required. For example, it insulates wiring in aircraft and spacecraft, where exposure to harsh environments and extreme temperatures is common.

FEP tubing is widely employed in commercial and medical electronics due to its flexibility and ease of processing. It is commonly found in insulation for cables, connectors, and instrumentation wiring. FEP’s clarity also allows visual inspection of the conductor or fluid inside, which is valuable in some specialized electrical and medical applications.

In summary, PTFE excels in high-temperature, high-performance electrical insulation, while FEP offers a versatile, flexible, and moisture-resistant alternative for a wide range of wiring and electronic uses.

PTFE cannot be melted like many other plastics. Instead, it requires special processing methods such as ram extrusion, compression molding, or sintering. This is because PTFE decomposes before it melts, so it doesn’t have a true melting point. These unique processing needs make PTFE more challenging and costly to manufacture into tubing or other shapes. The equipment must handle high pressures and temperatures carefully to achieve the desired product quality. This complexity also limits the shapes and sizes that can be produced easily.

FEP, unlike PTFE, can be melt-processed. It melts at a lower temperature, allowing it to be extruded, molded, and welded using conventional plastic processing techniques. This melt processability simplifies manufacturing, reducing production times and costs. FEP tubing can be made thinner and more uniform than PTFE tubing because of this. The ability to weld and re-mold FEP also enables fabrication of complex shapes and assemblies with relative ease. These processing advantages make FEP a popular choice when flexibility in design and cost efficiency are important.

Due to its complex processing, PTFE tubing tends to be more expensive than FEP tubing. The specialized equipment and longer production times add to its cost. However, PTFE’s superior properties often justify the higher price in demanding applications needing extreme chemical resistance, high temperature tolerance, or mechanical durability.

FEP’s simpler processing results in lower manufacturing costs. This makes FEP tubing a cost-effective option for applications where slightly lower temperature resistance and mechanical strength are acceptable. Its melt processability also allows for faster production and easier customization, which can reduce lead times and overall project costs.

When choosing between PTFE and FEP tubing, consider both performance needs and budget constraints. PTFE provides unmatched durability and thermal stability but at a premium price. FEP offers a balance of good performance, flexibility, and affordability.

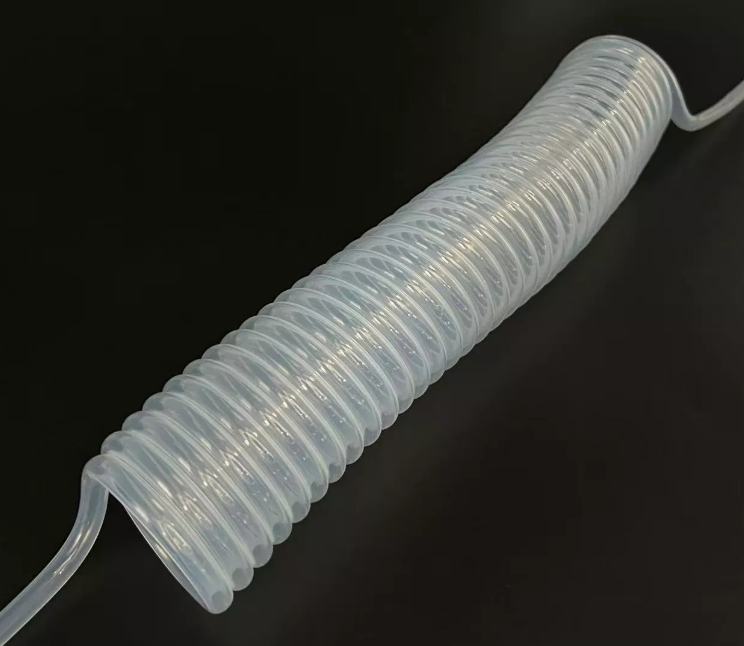

One of the most noticeable differences between PTFE and FEP tubing lies in their transparency. FEP tubing is naturally clear, allowing light to pass through with minimal distortion. This clarity makes it ideal for applications where visual monitoring of fluids or processes inside the tubing is necessary. For instance, in chemical processing or laboratory setups, operators can easily observe flow rates, detect bubbles, or identify contamination without interrupting the system. PTFE tubing, in contrast, is typically opaque or translucent, limiting its use where visibility is a priority.

FEP also outperforms PTFE in resistance to ultraviolet (UV) light and gamma radiation. It withstands prolonged exposure to sunlight and harsh lighting conditions without significant degradation. This UV resistance makes FEP tubing suitable for outdoor applications or environments with intense lighting. Moreover, FEP tolerates gamma radiation doses up to about 50 kGy, substantially higher than PTFE's tolerance of around 5 kGy. While both materials can degrade under extreme radiation, FEP’s superior resistance extends its usability in medical sterilization, nuclear facilities, and other radiation-prone environments.

Thanks to its clarity and radiation resistance, FEP tubing is favored in applications demanding both visibility and durability under radiation. Examples include:

● Sight glasses and flow indicators: Clear FEP tubing allows operators to visually inspect fluid flow and detect impurities in real time.

● Medical and pharmaceutical equipment: FEP tubing’s ability to endure sterilization processes involving gamma radiation ensures safety and longevity.

● Outdoor chemical processing: UV resistance protects the tubing from sunlight damage, maintaining performance in exposed settings.

● Nuclear and radiation environments: FEP tubing’s higher radiation tolerance supports use in systems exposed to gamma rays or other ionizing radiation.

In these scenarios, FEP’s unique combination of transparency and radiation resistance provides a significant advantage over PTFE tubing.

PTFE and FEP tubing differ primarily in chemical structure, affecting their properties and applications. PTFE, a homopolymer, offers high thermal stability and chemical resistance, while FEP, a copolymer, provides flexibility and easier processing. Choosing the right material depends on specific needs, such as PTFE for high-temperature resistance and FEP for transparency and radiation tolerance. VSJOCO's products deliver exceptional value, combining these unique benefits with reliable service, ensuring optimal solutions for diverse industrial requirements.

A: An FEP tube is a type of tubing made from fluorinated ethylene propylene, a copolymer of tetrafluoroethylene and hexafluoropropylene, known for its flexibility and transparency.

A: FEP tubing is more flexible than PTFE due to its copolymer structure, which allows for easier processing and bending without cracking.

A: Choose an FEP tube for applications requiring transparency, moderate chemical resistance, and cost-effective processing.

A: FEP tubes are generally more cost-effective than PTFE tubes due to easier processing and lower manufacturing complexity.

A: FEP tubes can handle temperatures up to +205°C (+400°F), making them suitable for moderate heat applications.