close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-10-14 Origin: Site

Ever wondered what makes FEP tubing a preferred choice in industries? FEP, or Fluorinated Ethylene Propylene, offers exceptional chemical resistance, crucial for handling aggressive substances. In this article, you'll learn about FEP's composition, its unique properties, and why chemically inert FEP tubing is essential in various applications.

FEP stands for Fluorinated Ethylene Propylene. It is a copolymer made from tetrafluoroethylene and hexafluoropropylene. This combination gives FEP unique properties. About 15% of its composition is hexafluoropropylene, which modifies the base polytetrafluoroethylene (PTFE) structure. Unlike PTFE, FEP is a thermoplastic, meaning it melts at a defined temperature and can be molded or extruded. This makes it easier to process compared to PTFE, which is not melt-processable.

FEP's molecular structure is fully fluorinated, which means every carbon atom is surrounded by fluorine atoms. This arrangement creates a strong bond that resists chemical attack. However, FEP also has side chains that slightly reduce its melting point compared to PTFE. Typically, FEP melts between 250°C and 270°C, while PTFE melts around 327°C. These side chains allow FEP to be flexible and easier to shape.

FEP tubing offers several important features that make it valuable across industries:

● Chemical Inertness: FEP resists most chemicals, including acids, bases, and solvents. It only reacts with a few substances like molten alkali metals and elemental fluorine at high temperatures.

● Temperature Range: It works well from very low temperatures (around -200°C) up to about 200°C continuously. It can tolerate short exposures to even higher temperatures.

● Electrical Insulation: The material has excellent dielectric properties. Its dielectric constant stays around 2.1 across a wide temperature and frequency range, making it ideal for insulating wires and cables.

● Low Friction: FEP has a low coefficient of friction. This helps reduce wear and tear when tubing moves or rubs against other surfaces.

● Flexibility: Compared to PTFE, FEP is softer and more flexible. This makes it easier to install in tight spaces or complex systems.

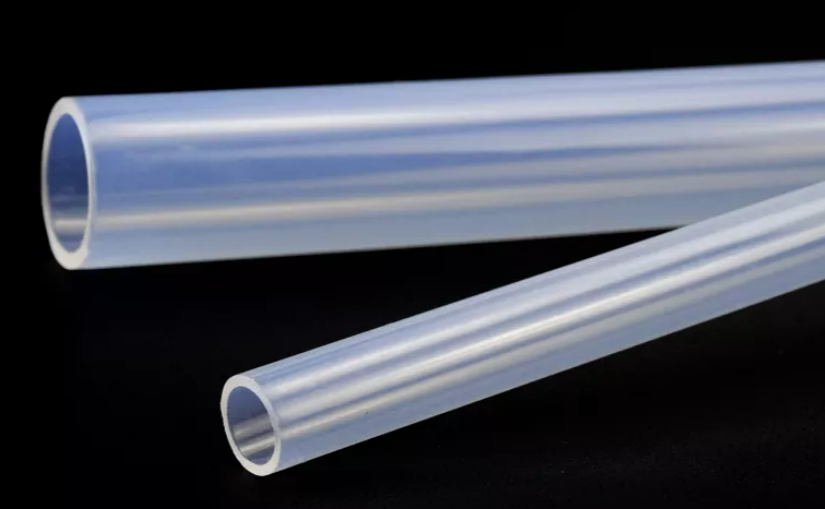

● Transparency: FEP tubing is often clear or translucent, allowing visual inspection of fluids inside.

● Flame Resistance: It does not ignite easily and prevents flame spread, adding safety in various applications.

● Weatherability: FEP resists UV radiation and weathering, making it suitable for outdoor use.

FEP tubing is commonly used in chemical processing, medical devices, electronics, and aerospace industries due to these characteristics. Its ability to combine chemical resistance with ease of processing sets it apart from other fluoropolymers.

FEP tubing is highly chemically inert. This means it resists almost all chemicals it encounters. The fluorine atoms surrounding the carbon backbone form strong bonds, creating a shield that prevents chemical attack. As a result, FEP tubing remains stable and does not react with most acids, bases, solvents, and oxidizing agents.

However, there are a few exceptions. FEP can be attacked by molten alkali metals, elemental fluorine, and some fluorine precursors, especially at elevated temperatures. Despite these rare cases, it performs exceptionally well in most chemical environments. This inertness makes FEP tubing suitable for handling aggressive fluids without degrading or contaminating them.

Its chemical resistance also contributes to its excellent weatherability and UV resistance. FEP tubing can be used outdoors and in harsh environments without losing its properties or breaking down. This durability is a key reason for its popularity in various industrial and laboratory settings.

FEP tubing shares many chemical resistance traits with other fluoropolymers such as PTFE (polytetrafluoroethylene) and PFA (perfluoroalkoxy alkane). All three materials resist a broad spectrum of chemicals due to their strong carbon-fluorine bonds.

● PTFE: Known as one of the most chemically inert materials, PTFE resists virtually all chemicals except molten alkali metals and elemental fluorine at high temperatures. It has a higher melting point than FEP but is not melt-processable.

● PFA: Offers chemical resistance similar to PTFE but with better processability and flexibility. It handles high temperatures slightly better than FEP.

● FEP: Combines excellent chemical resistance with easier processing due to its thermoplastic nature. Its temperature range is slightly lower than PTFE and PFA but sufficient for most applications.

Compared to non-fluoropolymer materials like PVC or PEEK, FEP and its fluoropolymer cousins provide superior chemical inertness. PVC, for example, can swell or degrade when exposed to ketones, esters, or aromatic hydrocarbons, limiting its use in aggressive chemical environments.

In summary, FEP tubing offers a balance of chemical resistance, flexibility, and ease of manufacturing. Its performance is close to PTFE and PFA, making it a versatile choice for many chemical handling applications.

FEP tubing's chemical inertness makes it a top choice across many industries. In chemical processing plants, it handles aggressive acids, bases, and solvents without degrading or contaminating fluids. Its resistance to harsh chemicals ensures long service life in pipelines, reactors, and valves.

In the food and beverage industry, FEP tubing safely transports liquids and gases without risk of contamination. Its FDA compliance in many grades supports hygienic applications.

The electronics sector uses FEP tubing for insulating wires and cables. Its excellent dielectric properties and chemical resistance protect delicate electronics from moisture and corrosive environments.

In aerospace, FEP tubing serves as protective sheaths for wiring and fluid transfer lines. Its resistance to UV rays and weathering suits outdoor and high-altitude conditions.

FEP tubing is widely used in medical devices and laboratories due to its biocompatibility and chemical stability. It transports pharmaceuticals and biological fluids safely, without leaching or reactions.

In laboratories, FEP tubing handles aggressive reagents and solvents during chemical analysis or synthesis. Its transparency allows visual monitoring of fluid flow and clarity.

Its flexibility and ease of sterilization make it ideal for catheters, IV lines, and other medical tubing. FEP tubing withstands repeated sterilization cycles, including autoclaving, without losing integrity.

Additionally, FEP tubing is used in diagnostic equipment and fluid delivery systems, where purity and chemical resistance are critical.

FEP tubing stands out for its exceptional durability. Its chemical inertness means it resists degradation from most chemicals, extending its service life. This resistance helps prevent leaks, cracks, or failures in harsh environments. The material also withstands repeated sterilization cycles, making it ideal for medical and laboratory use.

Besides chemical resistance, FEP offers excellent mechanical properties. It has good tensile strength and flexibility, which reduce the risk of damage from bending or vibration. The tubing maintains integrity even in extreme cold, down to about -200°C, and can handle continuous temperatures up to 200°C. This wide temperature range supports long-term use in various industrial processes.

FEP’s resistance to UV radiation and weathering adds to its durability outdoors. It does not become brittle or discolor after prolonged exposure to sunlight or moisture. This makes it a reliable choice for applications exposed to the elements, such as aerospace wiring or outdoor chemical lines.

Safety is a key advantage of FEP tubing. Its flame resistance helps prevent fires from spreading, enhancing protection in sensitive environments. The low coefficient of friction also reduces wear, lowering the chance of tubing failure that could cause leaks or contamination.

FEP is biocompatible and non-toxic, which is crucial for medical, pharmaceutical, and food-grade applications. It does not leach harmful substances into fluids, ensuring purity and safety. This quality also supports regulatory compliance, such as FDA approvals for food contact.

From an environmental perspective, FEP’s long lifespan reduces waste by minimizing tubing replacements. Its thermoplastic nature allows recycling or reprocessing in some cases, unlike thermoset materials. However, proper disposal and recycling protocols remain important due to fluoropolymer persistence.

In summary, FEP tubing offers a blend of durability, safety, and environmental benefits. These advantages make it a preferred material for industries requiring reliable, chemically resistant tubing solutions.

FEP tubing performs well across a broad temperature range but has limits to consider. It typically handles continuous use from about -200°C up to 200°C. Beyond this, its properties may degrade. For example, at temperatures above 200°C, FEP's mechanical strength can decrease significantly over time. This means it may become less durable and more prone to wear or damage if exposed to high heat continuously.

Short-term exposure to temperatures near its melting point (around 250°C to 270°C) is possible but not recommended for long-term applications. Prolonged heat near or above these levels can cause thermal decomposition, releasing gases such as tetrafluoroethylene and hexafluoropropylene. Proper ventilation is crucial during processing at elevated temperatures to avoid inhaling harmful fumes.

Compared to PTFE, which withstands higher continuous temperatures (up to about 260°C), FEP has a slightly lower upper temperature limit. This trade-off comes with the benefit of easier processing and flexibility. Users must evaluate temperature demands carefully to avoid premature tubing failure.

FEP tubing generally costs more than common plastics like PVC but less than PTFE. Its price reflects the specialized fluoropolymer chemistry and manufacturing process. While more expensive upfront, FEP's chemical resistance and durability often reduce replacement frequency and downtime, offering long-term savings.

However, budget constraints may limit its use in some applications. For projects requiring extreme temperature resistance or the highest chemical inertness, PTFE or PFA might be preferred despite higher costs. Conversely, less demanding uses might opt for cheaper materials like PVC or PEEK.

Additionally, because FEP is a thermoplastic, it requires careful handling during fabrication to maintain quality, which can add to production costs. Recycling options exist but are limited due to fluoropolymer persistence in the environment, potentially increasing disposal expenses.

Balancing performance, lifespan, and budget is key. FEP tubing fits best where chemical resistance and flexibility are priorities, but temperature extremes or cost sensitivity might necessitate alternatives.

When choosing tubing, FEP often competes with PTFE, PFA, and other materials like PEEK or PVC. Each has unique strengths and weaknesses.

● PTFE (Polytetrafluoroethylene):PTFE is the gold standard for chemical resistance. It resists nearly all chemicals except molten alkali metals and elemental fluorine at high temperatures. It handles continuous temperatures up to about 260°C, higher than FEP's 200°C limit. However, PTFE cannot be melt-processed, making it harder to shape or extrude compared to FEP. PTFE is stiffer and less flexible, which can be a drawback in tight spaces.

● PFA (Perfluoroalkoxy alkane):PFA offers chemical resistance similar to PTFE but with improved processability and flexibility. It withstands higher temperatures than FEP, usually up to 260°C continuously. PFA is melt-processable like FEP but tends to be more expensive. Its transparency and flexibility make it ideal for applications requiring visual inspection and bending.

● FEP (Fluorinated Ethylene Propylene):FEP combines excellent chemical resistance with easier processing and flexibility. It operates well between -200°C and 200°C. Its lower melting point allows for extrusion and molding. FEP is often more cost-effective than PFA but less heat resistant.

● PEEK (Polyether ether ketone):PEEK offers good chemical resistance, especially to organic solvents and acids, but is not as inert as fluoropolymers. It withstands higher temperatures (up to about 250°C) and has excellent mechanical strength. However, PEEK is opaque and less flexible, limiting its use in some fluid handling applications.

● PVC (Polyvinyl chloride):PVC is a low-cost option with decent chemical resistance to many acids and bases. However, it degrades when exposed to ketones, esters, and aromatic hydrocarbons. It also swells and loses strength in some solvents. PVC is easy to process but unsuitable for highly aggressive chemicals.

Choosing the best tubing depends on your application's chemical exposure, temperature range, flexibility needs, and budget.

● For extreme chemical resistance and high temperatures, PTFE or PFA are top choices.

● If ease of processing and flexibility are priorities, FEP is a strong candidate.

● When mechanical strength and temperature resistance matter more than chemical inertness, PEEK might work.

● For cost-sensitive projects with mild chemical exposure, PVC can be suitable.

Consider these factors:

● Chemical compatibility: Check if the tubing resists the specific chemicals used.

● Temperature range: Ensure the tubing handles both continuous and peak temperatures.

● Mechanical properties: Flexibility, tensile strength, and abrasion resistance.

● Regulatory requirements: Such as FDA compliance for food or medical use.

● Cost and availability: Balance performance with budget constraints.

Consult chemical resistance charts and, if possible, test small samples under your conditions. This helps avoid premature tubing failure and costly downtime.

FEP tubing is highly chemical resistant, making it suitable for handling aggressive fluids without degrading. Its flexibility and ease of processing enhance its versatility in various applications. FEP tubing is ideal for industries such as chemical processing, electronics, and medical devices. Choosing FEP tubing ensures durability and safety in challenging environments. For reliable and high-quality FEP tubing, consider products from VSJOCO, which offer unique benefits and value through exceptional chemical resistance and flexibility.

A: An FEP tube is made from fluorinated ethylene propylene, a thermoplastic copolymer known for its chemical inertness, flexibility, and resistance to UV radiation and weathering.

A: Chemically inert FEP tubing is easier to process and more flexible than PTFE, but has a slightly lower temperature resistance.

A: FEP tubing is preferred for chemical processing due to its broad chemical resistance, durability, and ability to handle aggressive fluids without degrading.

A: FEP tubing is more expensive than PVC but less costly than PTFE, offering long-term savings through reduced replacement frequency and downtime.

A: FEP tube benefits medical applications with its biocompatibility, chemical stability, and ability to withstand repeated sterilization cycles without losing integrity.