close

Choose Your Site

Global

Social Media

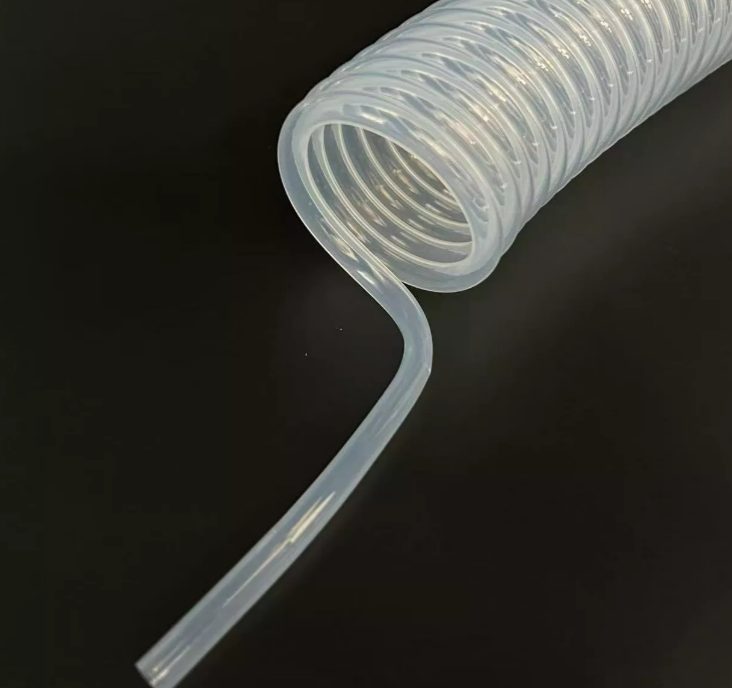

Have you ever wondered what makes FEP tubing so special? This remarkable material combines flexibility, chemical resistance, and transparency. In this post, you'll learn what FEP tubing is, its properties, and diverse applications across industries.

FEP, or Fluorinated Ethylene Propylene, is a type of fluoropolymer made by copolymerizing ethylene and hexafluoropropylene. This thermoplastic material combines excellent chemical stability and thermal resistance, making it ideal for many applications. FEP tubing is flexible, tough, and can be manufactured in continuous lengths, which suits fluid handling and chemical transfer uses.

One key feature of FEP is its translucent appearance, which allows light to pass through, making it useful where visual inspection of fluids inside the tubing is necessary. It also resists UV light and weathering well, so it maintains performance outdoors or under harsh conditions.

FEP shares many properties with PTFE (Polytetrafluoroethylene), another well-known fluoropolymer. Both materials resist chemicals strongly and have low friction surfaces. However, FEP differs in several important ways:

● Formability: FEP melts at a lower temperature (around 260°C) compared to PTFE, allowing easier melt processing. This makes FEP tubing easier and more cost-effective to produce in long continuous lengths.

● Flexibility: FEP is softer and more flexible than PTFE, though it does not handle repeated folding as well.

● Transparency: Unlike PTFE, which is opaque, FEP is highly transparent. This transparency helps in applications requiring visual fluid monitoring.

● Thermal Limits: PTFE can withstand slightly higher continuous temperatures than FEP. FEP’s upper service temperature is around 200°C, while PTFE can go higher.

● Surface Properties: Both have non-stick surfaces, but FEP has a slightly higher coefficient of friction.

● Chemical Resistance: Both are chemically inert, but PTFE is considered marginally more resistant to certain aggressive chemicals.

● Electrical Properties: Both have excellent dielectric strength, but FEP offers a low dielectric constant and dissipation factor, making it suitable for electrical insulation.

In summary, FEP tubing offers a balance of chemical resistance, flexibility, and optical clarity, while PTFE excels in higher temperature resistance and slightly better chemical inertness.

FEP tubing stands out for its exceptional resistance to a wide range of chemicals. It handles strong acids, bases, and organic solvents without degrading or reacting. This makes it ideal for harsh chemical environments, ensuring durability and safety during fluid transfer. Whether in labs or industrial settings, FEP tubing maintains its integrity when exposed to corrosive substances.

This tubing performs well under extreme temperatures, from as low as -200°C up to about 200°C. It retains its mechanical strength and flexibility throughout these ranges. Such thermal stability allows FEP tubing to be used in processes requiring sterilization or exposure to heat without risk of melting or cracking. It also withstands cold environments, making it versatile for various applications.

FEP tubing has a smooth, non-stick surface that prevents materials from adhering to it. This property reduces contamination risks and makes cleaning easier. In fluid handling, this means less buildup inside the tube, maintaining flow efficiency. The non-stick nature also helps in applications where low friction is crucial, such as in medical devices or precise chemical delivery systems.

One of FEP tubing’s unique advantages is its high clarity. It allows light to pass through, enabling visual monitoring of fluids inside. This transparency is valuable in laboratories and medical settings where observing fluid flow or detecting impurities is necessary. Unlike opaque materials, FEP tubing helps users quickly identify blockages or changes in fluid color.

FEP offers excellent electrical insulation properties. It has a high dielectric strength and a low dielectric constant, making it reliable for use in electrical and electronic applications. This means it can safely insulate wires or components exposed to high voltages. Its stability under electrical stress adds to its versatility beyond just fluid transfer.

FEP tubing’s unique properties make it highly versatile across many industries. Its chemical resistance, thermal stability, and transparency open doors to a wide range of uses.

One of the most common uses of FEP tubing is chemical transfer. It handles aggressive acids, bases, and solvents without degrading or reacting. This makes it perfect for transporting corrosive fluids safely in industrial plants and laboratories. Its non-stick surface prevents build-up inside the tube, ensuring smooth flow and reducing maintenance needs.

In medicine, FEP tubing is valued for biocompatibility and sterilization tolerance. It’s used in devices like catheters and endoscopes because it resists harsh chemicals and can withstand sterilization temperatures up to 200°C. The tubing’s smooth surface minimizes tissue damage during procedures. Its clarity also helps clinicians observe fluid flow or detect blockages during treatment.

Labs rely on FEP tubing for fluid handling when chemical inertness and visual monitoring are essential. The tubing’s transparency allows researchers to watch reactions or fluid movement inside the tube. It resists contamination and withstands repeated exposure to solvents and temperature changes, making it a dependable choice for experiments.

FEP tubing suits food and beverage industries due to its non-toxic nature and compliance with FDA standards. It resists staining and odors, maintaining purity in fluid transfer. Its ability to handle both hot and cold liquids without degrading ensures safe processing and cleaning, crucial for hygiene standards.

The semiconductor industry demands ultra-pure materials to avoid contamination. FEP tubing’s chemical inertness and low particle generation make it ideal for transporting ultra-pure chemicals and gases. Its transparency helps operators monitor flow visually, ensuring process integrity during manufacturing.

FEP catheters are widely used in medical applications due to their excellent physical and chemical properties. They feature a very smooth, non-stick surface, which reduces friction and minimizes tissue damage during insertion and movement. This smoothness helps lower patient discomfort and decreases the risk of complications. FEP’s chemical resistance is outstanding, able to withstand exposure to strong acids, bases, and organic solvents commonly encountered in medical treatments. It also tolerates sterilization temperatures up to about 200°C, allowing repeated high-temperature sterilization without degradation. Additionally, FEP maintains flexibility and strength at very low temperatures, making it suitable for cryotherapy applications. Its biocompatibility ensures it does not irritate human tissue, making it safe for long-term implantation.

Intravascular therapy requires materials that can safely navigate blood vessels without causing harm or reacting with bodily fluids. FEP catheters are ideal here because of their smooth surface and chemical inertness. They are often used for procedures like angiography and stent implantation, where precise placement and compatibility with body tissues are critical. The tubing’s flexibility allows it to move through narrow or curved vessels without kinking or breaking. Its resistance to sterilization methods ensures the catheter remains safe and effective for multiple uses.

Endoscopy demands tubing that can handle harsh sterilization while maintaining clarity and chemical resistance. FEP catheters meet these needs, allowing doctors to insert instruments smoothly and safely. Their non-stick nature prevents residue buildup, ensuring clear visibility and smooth operation. For drug delivery, FEP tubing offers precise control of fluid flow due to its smooth interior surface. This helps deliver medication accurately and consistently. The tubing’s chemical resistance also prevents interaction with drugs, maintaining their purity and effectiveness during administration.

Beyond catheters, FEP tubing is used to manufacture drainage tubes, breathing tubes, and other medical devices requiring biocompatibility and durability. Its resistance to chemicals and temperature, combined with flexibility and clarity, makes it a versatile choice in healthcare. As medical technology advances, FEP tubing’s role continues to grow, supporting safer, more comfortable patient care.

FEP and PTFE both offer outstanding chemical inertness, making them excellent choices for handling aggressive chemicals. They resist strong acids, bases, and organic solvents without breaking down or reacting. PTFE, however, has a slight edge in chemical resistance, especially against highly aggressive or concentrated chemicals. This makes PTFE often preferred in the most demanding chemical environments.

FEP, while highly resistant, can be more susceptible to swelling or permeability in some chemicals compared to PTFE. Still, it performs well enough for most industrial and medical applications. Both materials resist corrosion, ensuring long service life and safety when transferring hazardous fluids.

Permeability is another key difference. PTFE has a very low permeability to gases and liquids, making it nearly impermeable. FEP, on the other hand, has higher permeability, which can be a consideration in applications requiring strict containment of gases or vapors.

Regarding FDA approval, both FEP and PTFE are generally recognized as safe for food and medical use. However, FEP tubing often has broader FDA acceptance for direct food contact due to its melt-processability and ease of manufacturing in clean conditions. This makes FEP a common choice in food processing and pharmaceutical industries where regulatory compliance is critical.

Property | FEP Tubing | PTFE Tubing |

Chemical Resistance | Excellent, slightly less than PTFE | Superior, best for harsh chemicals |

Thermal Stability | Up to ~200°C | Up to ~260°C |

Flexibility | More flexible, softer | Stiffer, less flexible |

Transparency | Highly transparent | Opaque |

Permeability | Higher permeability | Very low permeability |

FDA Approval for Food Use | Widely accepted | Accepted but less common in food |

Processing | Melt-processable | Requires special sintering process |

FEP tubing plays a vital role in aerospace due to its excellent chemical resistance and thermal stability. It serves as a release film during composite manufacturing, preventing adhesives like epoxy or carbon fiber resins from sticking to metal tooling. This helps maintain the quality of aerospace parts while allowing easy removal after curing. Its resistance to UV radiation and weathering ensures durability in harsh flight environments. Additionally, FEP’s low friction and flexibility make it suitable for protective coatings on wiring and fluid transfer lines, where reliability under extreme conditions is critical.

Labs often use FEP tubing because it combines chemical inertness with high transparency. Researchers can visually monitor fluid flow, detect bubbles, or observe reactions inside the tubes. Its smooth, non-stick surface prevents contamination and buildup, which is crucial in experiments requiring purity. FEP tubing also withstands sterilization processes and extreme temperatures, making it reusable and reliable for repeated lab use. Moreover, its flexibility allows easy routing through complex setups, while its resistance to solvents and acids ensures longevity in demanding chemical environments.

In industries handling fluids, FEP tubing offers unmatched benefits. Its chemical resistance protects against corrosion from acids, bases, and solvents, extending service life. The tubing’s flexibility allows installation in tight or curved spaces without kinking. Its non-stick surface ensures smooth fluid flow and reduces clogging or residue buildup. Transparency helps operators visually inspect fluid conditions and detect blockages early. Common fluid handling uses include chemical dosing systems, coolant lines, and fuel transfer. FEP tubing’s dielectric strength also allows safe use near electrical components, enhancing safety in fluid systems.

FEP tubing, known for its chemical resistance, thermal stability, and optical clarity, is highly versatile across industries. It excels in fluid handling, medical devices, and aerospace applications, offering reliability and performance. Its unique properties make it ideal for demanding environments, ensuring durability and safety. VSJOCO provides high-quality FEP tubing tailored to meet specific needs, enhancing process efficiency and product quality. Choose VSJOCO for innovative solutions that deliver exceptional value in your applications.

A: An FEP tube is made from fluorinated ethylene propylene, offering chemical resistance, flexibility, and transparency, ideal for fluid handling and chemical transfer.

A: FEP tubing is used in catheters and endoscopes for its biocompatibility, sterilization tolerance, and smooth surface, minimizing tissue damage.

A: Choose FEP tubing for easier processing, flexibility, and transparency, while PTFE is better for higher temperatures and chemical resistance.

A: FEP tubing provides chemical resistance, thermal stability, non-stick surfaces, and transparency, making it versatile for various industries.