close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-10-22 Origin: Site

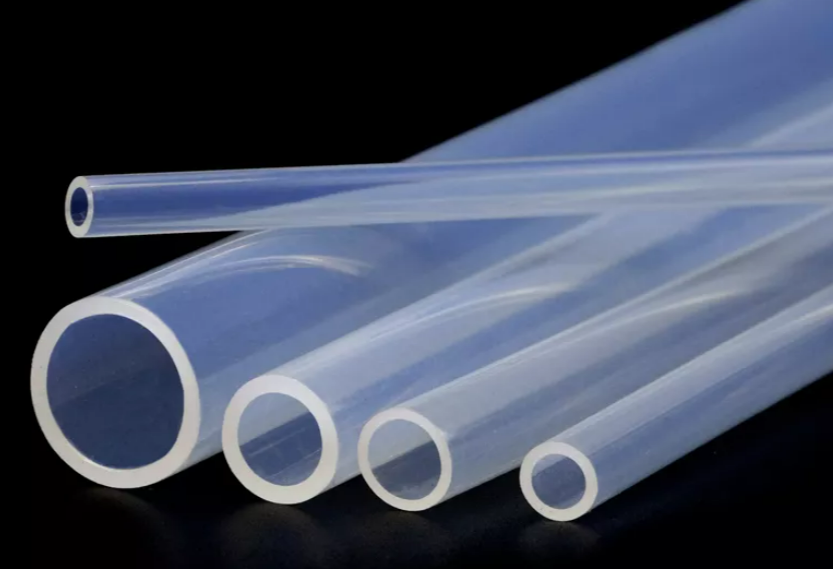

Ever wondered why FEP tubing is a popular choice in various industries? FEP tubing, known for its exceptional chemical resistance and flexibility, plays a crucial role in medical, chemical, and electronics sectors. In this post, you'll learn about its key properties and why FEP anti-static tubing is preferred for safe and efficient operations.

FEP tubing plays a vital role in the medical field due to its excellent chemical resistance and biocompatibility. It is often used in devices requiring fluid transfer, such as catheters, IV lines, and blood analyzers. Its smooth surface prevents contamination and buildup, making it ideal for sterile environments. Since it withstands repeated sterilization cycles, hospitals and labs prefer it for reusable medical equipment. Additionally, FEP tubing is transparent, allowing easy visual monitoring of fluids during medical procedures.

In chemical processing, FEP tubing handles aggressive chemicals safely and efficiently. Its resistance to acids, bases, and solvents prevents corrosion or degradation. This durability ensures long-lasting performance in harsh environments. Industries use it for transferring chemicals, sampling, and waste disposal lines. FEP tubing's non-stick surface reduces clogging and eases cleaning. It also tolerates high temperatures, making it suitable for processes involving heat. This tubing helps maintain product purity and operator safety by preventing leaks and chemical exposure.

FEP tubing serves crucial functions in electrical and electronics applications. It acts as insulation for wires and cables, protecting against heat, moisture, and chemicals. Its dielectric properties reduce electrical interference and improve signal quality. Electronics manufacturers use FEP tubing for cable jacketing, wire harnesses, and protective sleeving. Its flexibility allows easy routing in tight spaces, while its flame resistance enhances safety. In addition, FEP tubing prevents static buildup, which can damage sensitive electronic components.

FEP anti-static tubing helps prevent static electricity from accumulating during fluid or gas transfer. Static build-up can cause sparks or attract dust and particles, leading to contamination or even explosions in sensitive environments. The anti-static properties allow charges to dissipate safely, reducing risk. This feature makes FEP tubing ideal for applications involving flammable liquids, powders, or gases. It also protects electronic components from electrostatic discharge damage. Using anti-static FEP tubing ensures smoother, safer operations in industries where static control is critical.

Safety is a top priority in many industrial settings. FEP anti-static tubing enhances safety by minimizing static-related hazards. It reduces fire and explosion risks in chemical plants, refineries, and pharmaceutical factories. The tubing’s chemical resistance and durability add layers of protection against leaks and ruptures. Its flexibility and strength allow easy installation without compromising safety standards. Workers benefit from a safer environment, and companies avoid costly accidents or downtime. FEP anti-static tubing also meets various industry safety regulations, making it a trusted choice for demanding applications.

Sensitive environments such as cleanrooms, laboratories, and electronics manufacturing require tubing that won’t interfere with processes. FEP anti-static tubing maintains a clean, static-free environment, preventing contamination and equipment damage. Its smooth surface resists buildup and is easy to clean, supporting strict hygiene requirements. The tubing’s transparency helps monitor fluid flow, ensuring process accuracy. It performs well under extreme temperatures and exposure to chemicals, maintaining stability and reliability. Choosing FEP anti-static tubing improves overall system performance and product quality in these critical settings.

FEP (fluorinated ethylene propylene) and PTFE (polytetrafluoroethylene) tubing share many chemical and thermal resistant properties, but key differences affect their applications. FEP tubing offers greater flexibility than PTFE, making it easier to install in tight spaces or complex routing. PTFE tubing is stiffer and less transparent, which limits visual monitoring of fluids. FEP also melts at a lower temperature than PTFE, so it suits applications with moderate heat but not extreme temperatures. Both resist chemicals well, but PTFE generally withstands higher temperatures up to 260°C (500°F), compared to FEP’s maximum around 200°C (392°F). Choose PTFE for very high heat or abrasive environments; pick FEP when flexibility and clarity matter most.

PFA (perfluoroalkoxy alkane) tubing closely resembles FEP but features higher temperature tolerance and better mechanical strength. PFA can handle temperatures up to 260°C (500°F), similar to PTFE, while FEP maxes out near 200°C (392°F). PFA tubing also offers excellent chemical resistance and is transparent like FEP. However, PFA tends to be less flexible and more expensive than FEP. It’s ideal for applications demanding both high purity and high temperature. FEP tubing often fits better in budget-conscious projects requiring good chemical resistance and flexibility but lower heat resistance.

FEP tubing strikes a balance between performance and cost. It tends to be more affordable than PFA and PTFE, especially for medium-temperature applications. Its flexibility reduces installation time and labor costs, helping lower overall project expenses. The tubing’s durability means fewer replacements and less downtime, saving money long-term. While PTFE and PFA provide superior temperature resistance, they come at a premium price. For many industries, FEP tubing delivers excellent value by meeting chemical resistance, clarity, and flexibility needs without overspending.

Choosing the right FEP tubing starts by knowing your system’s temperature and pressure needs. FEP tubing generally handles temperatures up to about 200°C (392°F). If your process involves heat beyond this, consider alternatives like PFA or PTFE tubing. Pressure ratings vary depending on tubing diameter and wall thickness. Smaller diameters with thicker walls withstand higher pressures. Always check manufacturer specifications to ensure tubing can safely operate under your system’s conditions. Ignoring these ratings risks tubing failure, leaks, or safety hazards.

FEP tubing resists a wide range of chemicals, including acids, bases, and solvents. However, verifying compatibility for your specific chemicals is crucial. Some highly reactive substances or mixtures may degrade certain fluoropolymers over time. Use chemical compatibility charts or consult suppliers to confirm FEP suitability. Remember, chemical resistance also depends on temperature and exposure duration. Selecting incompatible tubing can lead to contamination, leaks, or premature wear, affecting system reliability and safety.

Tubing size impacts flow rates, pressure drop, and installation ease. Inner diameter controls fluid volume, while outer diameter affects fitting compatibility. Wall thickness influences strength and flexibility. Thicker walls increase pressure resistance but reduce flexibility. Thin walls improve bending but may not handle high pressures. Balance these factors based on your application needs. For example, medical devices often require smaller, thinner tubing for precision and comfort. Chemical transfer lines might need thicker walls to withstand harsh conditions. Accurate measurements ensure proper fit and performance.

Installing FEP tubing properly ensures long-lasting performance and safety. First, handle tubing carefully to avoid kinks or sharp bends that reduce flow or cause damage. Use tubing supports or clamps to maintain a smooth path and prevent stress points. When cutting tubing, always use a sharp blade or tubing cutter for clean, straight edges. This helps create tight, leak-free connections.

Select compatible fittings designed for FEP tubing, such as compression or push-to-connect types. Avoid over-tightening fittings, which can deform tubing or cause leaks. Instead, tighten fittings just enough to secure the tubing firmly. When routing tubing near heat sources, allow space or use insulation to prevent overheating. Also, avoid contact with sharp objects or abrasive surfaces that might wear the tubing over time.

Regular maintenance keeps FEP tubing functioning well and extends its life. Inspect tubing periodically for signs of wear, discoloration, or cracks. Replace any damaged sections immediately to avoid leaks or contamination. Clean tubing using compatible solvents or mild detergents, especially in medical or chemical applications. Avoid harsh scrubbing or abrasive cleaners that can damage the smooth tubing surface.

Check fittings and connections regularly to ensure they remain tight and leak-free. In systems handling fluids prone to buildup, flush tubing occasionally to remove deposits. For tubing exposed to static or dust, wipe surfaces clean to maintain anti-static properties. Document maintenance activities to track tubing condition and replacement schedules.

Common problems with FEP tubing include leaks, kinks, discoloration, and reduced flow. Leaks often result from loose fittings, damaged tubing ends, or incompatible connectors. Tighten fittings carefully or replace faulty parts to fix leaks. Kinks usually occur when tubing bends too sharply or lacks proper support. Re-route tubing or add clamps to straighten lines and prevent kinks.

Discoloration or cloudiness may indicate chemical attack or UV exposure. Replace tubing if discoloration affects performance or safety. Reduced flow can stem from blockages, kinks, or incorrect tubing size. Inspect tubing for obstructions and ensure diameter suits your application. If problems persist, consult tubing suppliers or experts for guidance.

FEP tubing continues evolving through material innovations. Manufacturers develop enhanced fluoropolymer blends that improve flexibility, toughness, and temperature resistance. New formulations aim to extend service life while maintaining chemical inertness. For example, some FEP variants now offer better abrasion resistance, reducing wear in harsh industrial environments. Others include additives to boost anti-static properties, helping applications sensitive to static discharge. Research also explores bio-based fluoropolymers, aiming to reduce environmental impact without sacrificing performance. These innovations promise tubing that adapts better to modern industry demands, combining durability and sustainability.

FEP tubing finds new uses beyond traditional sectors. The growing electric vehicle (EV) market uses FEP tubing for battery cooling and wiring insulation, thanks to its heat and chemical resistance. Renewable energy industries apply it in solar panel manufacturing and hydrogen fuel systems, where purity and safety are crucial. Food and beverage processing increasingly adopts FEP tubing for sanitary fluid transfer, leveraging its non-stick, easy-to-clean surface. Even aerospace benefits from lightweight, flexible FEP tubing for fuel lines and electronic wiring. These emerging applications show FEP tubing’s versatility across cutting-edge technologies.

Sustainability shapes future FEP tubing production and disposal. Manufacturers focus on reducing fluoropolymer waste by improving recycling methods. Some companies design tubing for easier disassembly and reuse, cutting landfill contributions. Research into lower-fluorine-content materials aims to lessen environmental persistence while retaining key properties. Additionally, energy-efficient production processes reduce carbon footprints. Users also consider tubing lifespan and maintenance to minimize replacements, supporting sustainability goals. Balancing performance with eco-friendliness remains a priority as industries push for greener solutions.

FEP tubing is vital in medical, chemical, and electronic industries due to its chemical resistance and flexibility. It is used for fluid transfer in medical devices, handling chemicals safely, and insulating electronic components. Future trends show FEP tubing expanding into electric vehicles, renewable energy, and aerospace, driven by innovations in material durability and sustainability. Companies like VSJOCO offer FEP tubing that combines performance with eco-friendly manufacturing, providing exceptional value and meeting diverse industry needs.

A: FEP tubing is used in the medical industry for fluid transfer in devices like catheters and IV lines due to its chemical resistance and biocompatibility.

A: FEP anti-static tubing enhances safety by minimizing static-related hazards, reducing fire and explosion risks, and meeting industry safety regulations.

A: FEP tubing is more flexible and affordable than PTFE, and better suited for moderate temperatures compared to PFA, offering excellent chemical resistance and clarity.