close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-10-20 Origin: Site

Have you ever wondered why FEP is favored in demanding industries? FEP, known for its exceptional heat resistance and chemical inertness, plays a vital role in tube manufacturing. This article explores the significance of FEP tubing, highlighting their unique properties. You'll learn how to select the right FEP for your needs, ensuring optimal performance and durability in various applications.

FEP resin, or Fluorinated Ethylene Propylene, stands out for its unique set of properties. It resists high temperatures, often up to 200°C, without losing its shape or performance. This makes it perfect for harsh environments. It also resists chemicals exceptionally well, handling acids, solvents, and oils without breaking down. Another key feature is its excellent electrical insulation, useful for protecting sensitive electronics. Plus, FEP is non-stick and has low friction, helping fluids flow smoothly through tubes made from it. These traits make FEP resin a versatile material in many fields.

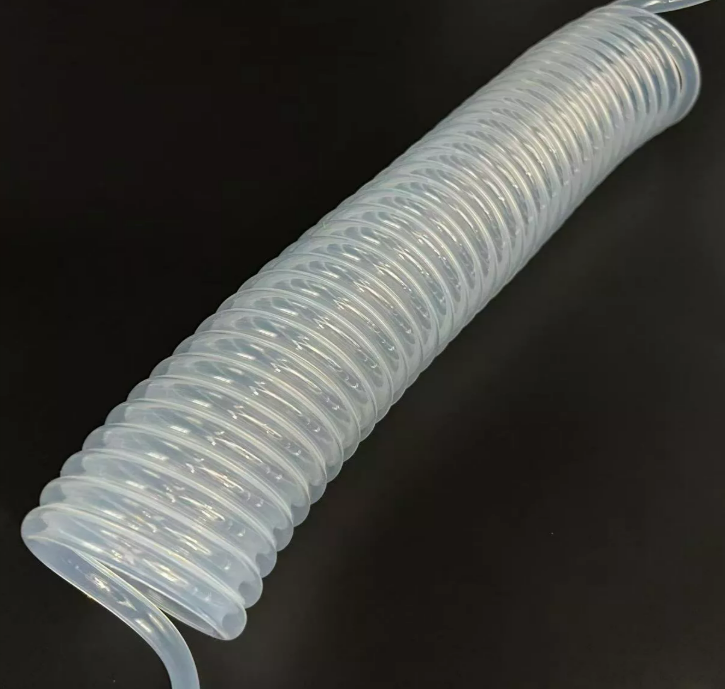

In tube manufacturing, FEP resin is a top choice. Its heat resistance means it works well in processes involving hot fluids or gases. Chemical resistance allows tubes to transport corrosive or reactive substances safely. The non-stick surface prevents buildup inside tubes, reducing maintenance needs. FEP tubes are often clear or translucent, allowing visual inspection of the contents or flow. Manufacturers use FEP resin to make tubes for medical devices, chemical processing, food and beverage handling, and even aerospace systems. Its flexibility and durability ensure tubes perform well under stress and bending.

Industries benefit greatly from FEP’s qualities. In medical fields, FEP tubing is biocompatible and safe for contact with tissues and fluids. It’s commonly used in catheters and surgical instruments. Chemical plants rely on FEP tubes for handling aggressive chemicals without corrosion or leaks. Food processing facilities appreciate FEP’s FDA compliance and non-toxic nature. Electronics manufacturers use FEP for insulating and protecting delicate wiring. Aerospace and automotive sectors take advantage of FEP’s lightweight, durable, and heat-resistant properties for fuel lines and wiring harnesses. This broad applicability makes FEP resin a valuable material across many sectors.

Temperature plays a huge role when picking the right FEP resin. Different grades handle heat differently. Some can resist temperatures up to 200°C, while others perform better at lower ranges. You need to know the highest temperature your application will face. For example, tubing used in chemical processing might see hot fluids, so a high-temp resistant resin is crucial. Using a resin that can’t handle the heat risks deformation or failure. Always check the continuous service temperature and peak temperature limits of the resin.

FEP is famous for chemical resistance, but not all grades resist every chemical equally. Some acids or solvents may attack certain resin types faster. Match the resin’s chemical resistance to the substances it will contact. Also, consider mechanical needs. Will the tubing bend a lot? Does it need to be stiff or flexible? Some FEP resins offer better flexibility, others are tougher or more abrasion-resistant. Mechanical properties affect durability and performance under stress.

Every application has unique demands. For medical tubing, biocompatibility and purity matter most. For food processing, FDA compliance and non-toxicity are key. Industrial uses might prioritize chemical resistance and mechanical strength. Aerospace applications often require weight savings and extreme temperature tolerance. Identify your exact needs before choosing a resin. Consider factors like transparency, electrical insulation, and ease of processing. Also, think about long-term durability and maintenance requirements.

Standard FEP resin is the most common type used in tube manufacturing. It offers a good balance of heat resistance, chemical inertness, and flexibility. This grade typically withstands continuous temperatures up to 200°C, making it suitable for many general applications. For example, standard FEP tubing often appears in food processing, medical devices, and basic chemical handling where moderate conditions apply. Its non-stick surface helps prevent material buildup inside tubes, reducing maintenance. Plus, it’s transparent or translucent, allowing easy visual inspection of fluid flow.

High-performance FEP resin is engineered for more demanding environments. It maintains stability and strength at higher temperatures or under harsher chemical exposure. This grade may offer enhanced mechanical properties such as improved abrasion resistance or tensile strength. Industries like aerospace, advanced chemical processing, or automotive systems often require this resin. For instance, fuel lines or wiring harnesses exposed to extreme heat and chemicals benefit from high-performance FEP. Choosing this grade helps prevent failures and extends service life in tough conditions.

Modified FEP resin includes additives or alterations to boost chemical resistance beyond the standard grade. This makes it ideal for handling aggressive acids, solvents, or other reactive substances that might degrade regular FEP. It also can improve properties like UV resistance or electrical insulation. Chemical plants or pharmaceutical manufacturing often rely on modified FEP resin to ensure safety and durability. For example, tubes transporting strong acids may use modified FEP to avoid corrosion and leaks. This grade provides peace of mind when chemical exposure is severe.

Choosing the right FEP resin grade starts with understanding your application’s exact needs. Ask questions like:

● What temperature range will the resin face?

● Which chemicals will it contact?

● Does the tubing need to be flexible or stiff?

● Is transparency important for inspection?

● Are there any industry standards or certifications required?

Clear answers help narrow down resin choices. For example, medical tubing demands biocompatibility and FDA compliance, while chemical processing pipes need excellent chemical resistance and high-temperature tolerance.

Once you know your requirements, compare them to the properties of available FEP grades:

Application Factor | Important Resin Property | Example Use Case |

High temperature | High continuous service temperature | Aerospace fuel lines |

Chemical exposure | Enhanced chemical resistance | Chemical plant tubing |

Flexibility | Good mechanical flexibility | Medical catheters |

Transparency | Optical clarity | Food and beverage tubing |

Biocompatibility | Medical-grade purity | Surgical instruments |

Matching these ensures the resin performs well and lasts long in your environment. Avoid over-specifying, which can increase costs unnecessarily.

Quality matters. Choose FEP resin that meets recognized standards like:

● ISO 9001 for quality management

● FDA approval for food and medical use

● RoHS and REACH for environmental safety

● ASTM standards for material properties

Certified resins provide assurance about consistency, safety, and compliance. Low-quality resin risks product failure, contamination, or regulatory issues.

Reputable suppliers often provide certificates and test reports. Always request these before purchasing.

Choosing FEP resin involves balancing quality and cost carefully. High-quality FEP often costs more upfront but delivers better performance, durability, and reliability. Cheaper grades may seem attractive initially but can lead to frequent replacements or failures, increasing overall expenses. Consider your application's demands before cutting costs. For example, tubing in harsh chemical environments needs resilient resin to avoid leaks or damage. Investing in quality minimizes downtime and maintenance, saving money over time.

High-grade FEP resin offers long-term savings beyond initial purchase price. Its superior chemical resistance and heat tolerance reduce wear and tear. This means fewer replacements and repairs, lowering labor and material costs. Also, high-quality resin maintains its properties longer, ensuring consistent performance. In critical industries like medical or aerospace, failure risks are costly. Using premium FEP reduces these risks, protecting your investment and reputation. Think of it as paying more now to avoid bigger costs later.

● Chemical Plant: A facility switched to high-performance FEP tubing for corrosive fluid transport. Though initially pricier, the tubing lasted twice as long as standard grades, cutting replacement costs by 50%.

● Food Processing: A company used standard FEP tubing meeting FDA standards. The balance of cost and compliance ensured safe product handling without overspending on unnecessary features.

● Medical Device Manufacturer: They chose modified FEP resin for enhanced chemical resistance in catheters. The upfront cost was higher, but the improved durability reduced warranty claims and recalls.

These examples show how selecting the right FEP grade tailored to application needs delivers cost efficiency and reliability.

Choosing FEP tubing often means customizing it to fit your exact needs. Tubing comes in many diameters and wall thicknesses, so picking the right size ensures a perfect fit for your application. Thin walls add flexibility, ideal for delicate or bending parts. Thicker walls boost durability, perfect for harsh environments or heavy use.

Colors help too. While FEP tubing is usually clear or translucent, adding color makes identification easier. Color coding can speed up assembly, reduce mistakes, and organize components, especially in medical, automotive, or industrial settings. Custom colors also improve the look of your products when aesthetics matter.

Many suppliers offer printing options on FEP tubing. You can add logos, serial numbers, or batch codes for traceability. This is vital in industries like medical devices or aerospace, where tracking parts ensures safety and compliance.

Markings can also include measurement guides to help cut tubing to the right length quickly. Advanced printing methods keep these markings clear despite exposure to chemicals or heat. This reduces errors and saves time during installation or maintenance.

Picking the right supplier is just as important as choosing the tubing itself. Always check for certifications like ISO 9001 (quality management), ISO 13485 (medical devices), FDA approval (food and pharma safety), and RoHS/REACH (environmental compliance). These prove the supplier meets strict quality and safety standards.

Good suppliers offer strong customer support. They help you select the right tubing, provide technical advice, and handle custom orders smoothly. Fast, reliable delivery matters too—delays can disrupt your projects and cost money.

Request samples before buying. Testing samples ensures the tubing fits your needs and performs well in your conditions.

FEP resin, known for its heat resistance, chemical inertness, and flexibility, is ideal for diverse applications. Selecting the right FEP involves considering temperature, chemical exposure, and mechanical needs. Quality and industry standards are crucial in ensuring reliable performance. Customization options like size, color, and printing enhance usability. Choosing a certified supplier guarantees product quality and support. VSJOCO offers premium FEP solutions, providing exceptional value with customized tubing options tailored to specific industry needs, ensuring efficiency and reliability.

A: An FEP tube is made from Fluorinated Ethylene Propylene resin, known for its heat resistance and chemical inertness, making it ideal for harsh environments and various industries.

A: Choose an FEP coiled tube by evaluating temperature resistance, chemical compatibility, and mechanical properties specific to your application needs.

A: FEP coiled tubes in medical devices offer biocompatibility, chemical resistance, and flexibility, ensuring safe contact with tissues and fluids.

A: FEP tubing's durability and resistance reduce maintenance and replacement costs, offering long-term savings despite higher upfront costs.